ABOUT GUOTE

Weifang Guote Mining Equipment Co., Ltd.

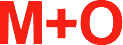

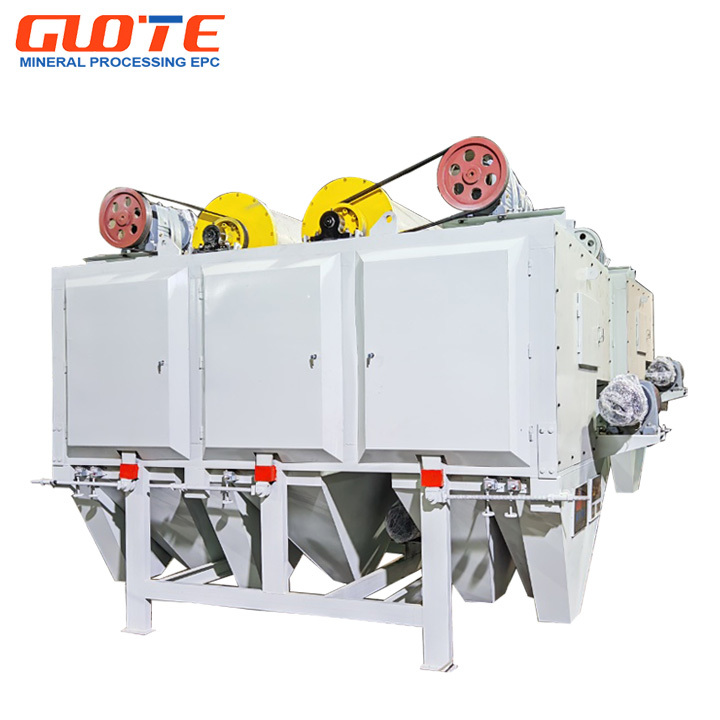

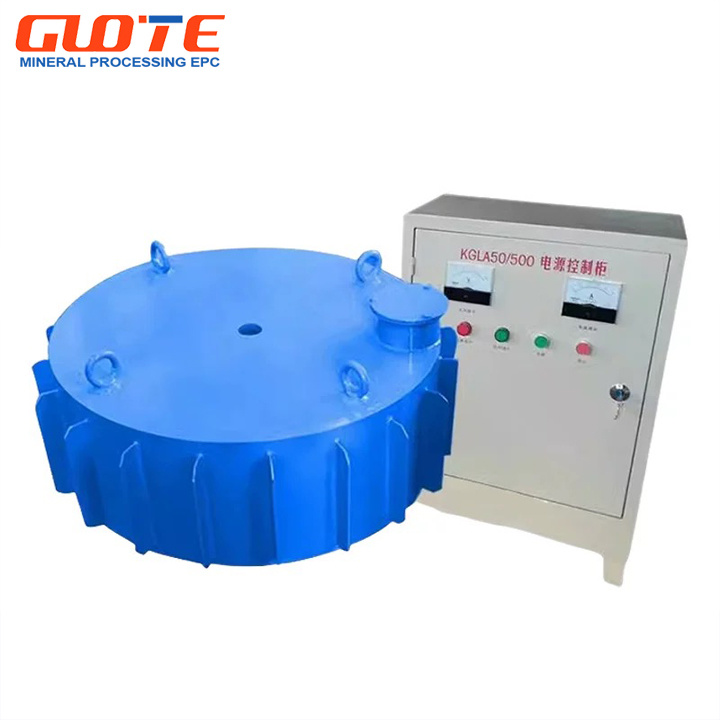

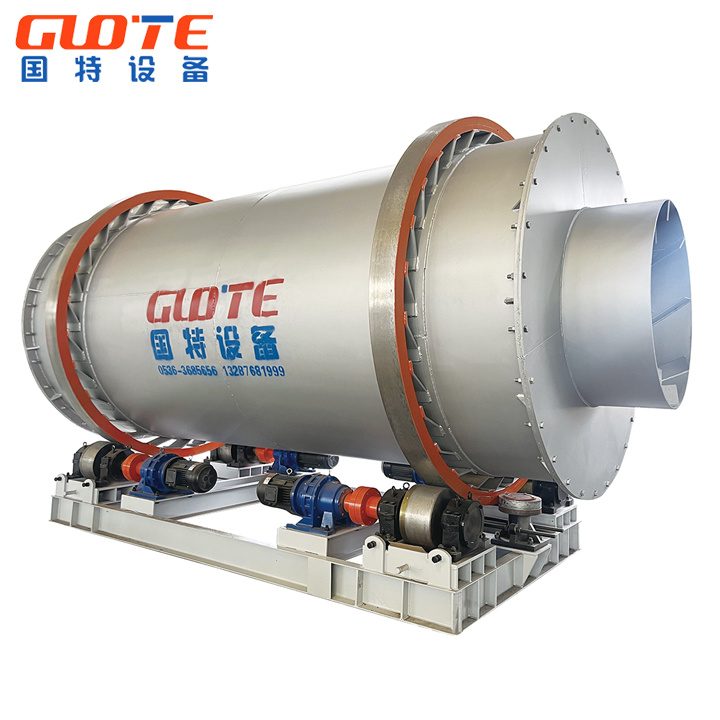

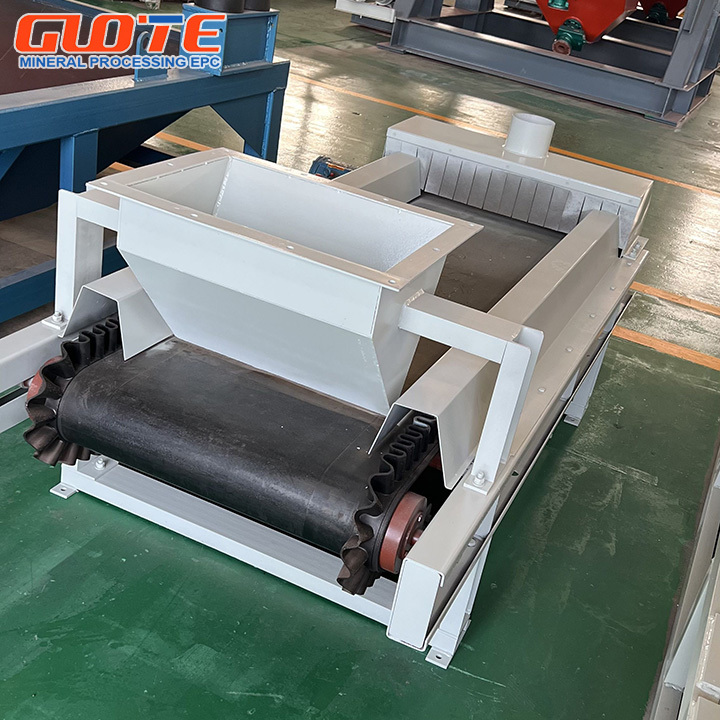

Weifang Guote Mining Equipment Co., Ltd. is located in Weifang City, Shandong Province, China.Since its establishment in 2013, it has experienced more than ten years of precipitation and has gradually grown and developed. Now its output value has exceeded hundreds of millions of yuan. The company strictly follows international industry standards in product quality control. Its products have passed ISO three major system certifications and EU CE certification. With its excellent R&D strength, the company has more than 100 patented technologies. The patents cover product design, process, function and other aspects, which makes the company's products have unique advantages in market competition. The company's products include non-metallic mineral production lines such as quartz glass sand, quartz plate sand, petroleum fracturing sand, silicon micropowder, hematite, manganese ore, ilmenite, limonite and other metal mineral production lines and magnetic separation, screening, sand washing, grading, drying, dehydration and other stand-alone products. The above products are independently developed and produced by the company. Each product embodies the wisdom and hard work of Guote people, and performs well in stability and reliability.The company currently has dozens of professional and technical personnel with rich practical experience in design, R&D and other aspects, and can provide customers with the best technical support and services at any time.The company has always adhered to the business philosophy of reliability, efficiency and simplicity. It can provide a service system integrating mineral processing experiments, engineering design, production installation and commissioning services according to the specific needs of customers, and provide customers with one-stop EPC solutions.Weifang Guote Mining Equipment Co., Ltd.'s products are exported to Southeast Asian countries such as South Korea, India, Malaysia, Vietnam, Indonesia, Africa, South America, Oceania and other regions, establishing a good image for the global mining equipment industry on the international stage and creating an international brand that is well-known at home and abroad.

View moreIt was established in 2013

Guote has more than 100 employees

50000 square meters

exported to more than 30 countries

Guote News

Guote Equipment has long been committed to the production and research and development of quartz sand, quartz plate sand, special equipment for quartz powder and vertical ring high gradient magnetic separator, and provides experiments, design, consultation and supply of the above production lines.