Introduction

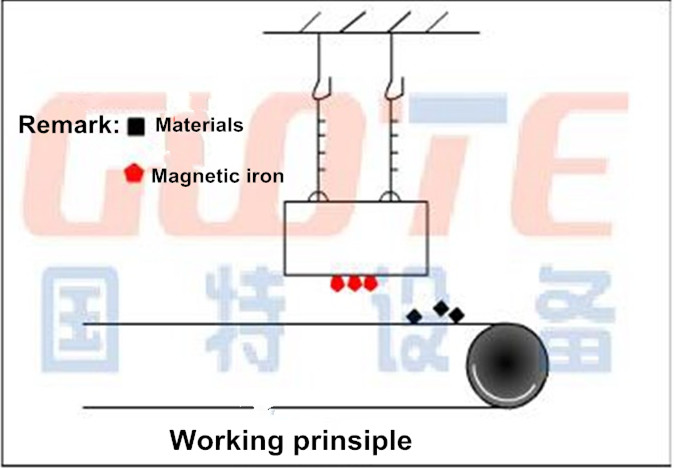

RCYB series suspended permanent magnet iron remover uses high coercivity, high remanence permanent magnet "neodymium iron boron" and other materials to form a composite magnetic system. It has the advantages of maintenance-free, strong magnetic force, simple installation, convenient use and stable operation. It is suitable for removing iron from non-magnetic materials on belt conveyors, vibrating conveyors, electromagnetic vibrating feeders, and unloading chutes. Excluding 0.1-35 kg of ferromagnetic materials, the permanent magnet system has a service life of more than 10 years. All indicators of this product are in line with the JB/T7689-2004 standard. When the permanent magnet adsorbs a lot of iron, it can be removed manually with a non-magnetic scraper or with gloves. It is suitable for continuous work and occasions with less iron. Can be customized according to user requirements.