Introduction

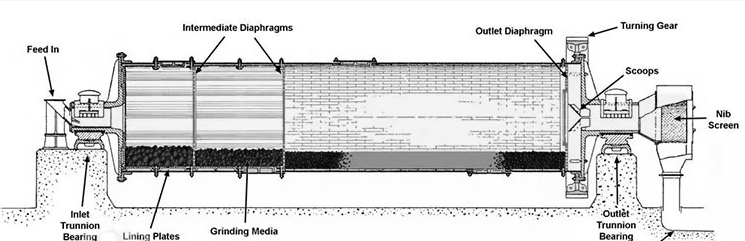

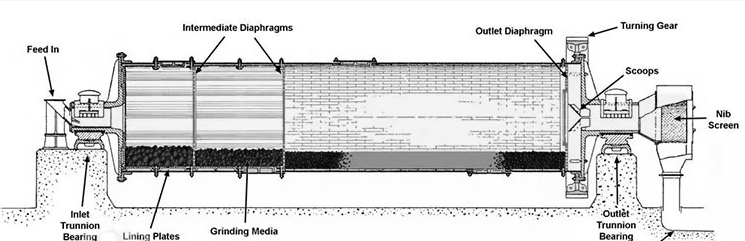

Ball mill machine is mainly composed of feeding part, discharging part, rotary part and driving part which includes reducer, small drive gear, electrical machine and electronic control. The hollow shaft uses steel casting, the inner lining can be dismantled and changed, and the rotary rack wheel uses casting gear hobbing and inside the cylinder there is wear-resisting lining board which has fine abrasion performance. This machine has stable operation and reliable performance.

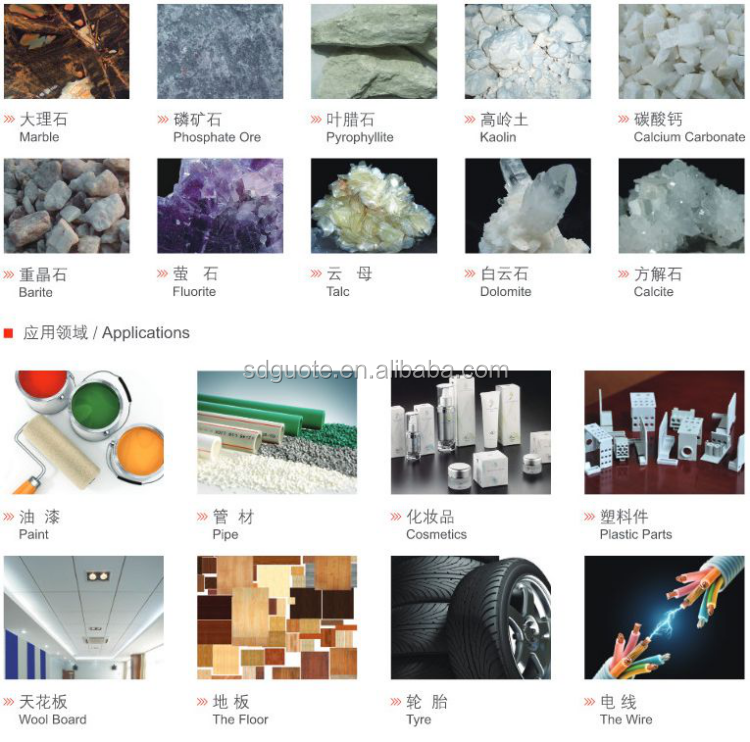

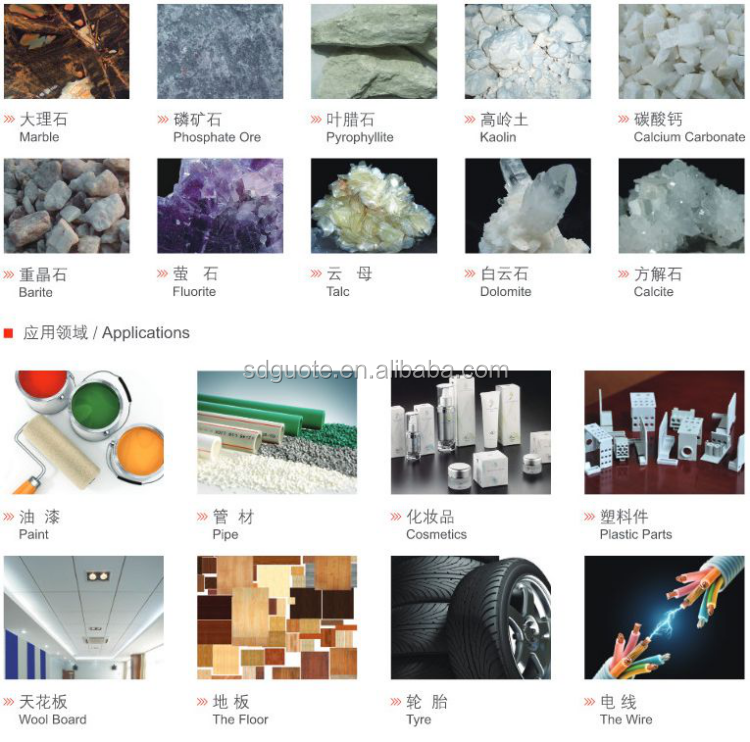

Application areas: mineral processing, chemicals, medicine, building materials, quartz powder for plates, etc. This product can be used to produce 200-1250 mesh high-purity quartz powder. The product has the advantages of high purity, good whiteness, and stable particle size. The whole production line can realize automatic control, and the equipment runs stably.

Advantages

The whole production process is protected by high-purity wear resistance. According to the difference in production conditions, the ball mill lining can be equipped with ceramic lining or quartz lining, and the grinding medium can be selected with ceramic balls or quartz balls. Contact with metal to ensure product purity and extend the service life of equipment

The grading impeller blades are made of polymer wear-resistant materials, which effectively solves the problem of wear of the grading impeller

PLC automatic control can be designed according to requirements, from grinding → grading → packaging, the whole process is automatically controlled, reducing labor intensity and saving production costs

Theory and practice optimize system configuration, reduce energy consumption to a minimum, scientific dust removal design at each dust point of the system, effectively control dust spillage, and meet national environmental protection requirements

According to the different requirements of customers, customized design and manufacturing, stable and reliable equipment operation

Good whiteness, stable particle size, in line with quartz plate filling material standards

Working Principle

Raw materials with less than -10 meshes are uniformly spiraled into the mill bin through the feeding hollow shaft from the feeding device. The bin is equipped with ceramic lining plates and equipped with steel balls of different specifications. The rotation of the cylinder generates centrifugal force to bring the media balls to a certain height. After falling, it will impact and grind the material. The powder that meets the requirements is discharged through the discharge grate to complete the grinding operation. The ground material enters the classifier from the inlet, and by adjusting the speed of the classifying wheel (frequency conversion control, stepless speed regulation), and matched with a reasonable secondary air inlet, a reasonable and stable gas-solid two-phase system is formed in the classification area. Phase flow, the centrifugal force generated by the rotation of the grading wheel, and the negative pressure of the induced draft fan generate attractive interaction to achieve effective classification of materials. The coarse particles are returned to the ball mill by the coarse material return device to continue grinding, and the finished product is packaged by the automatic packaging machine. The whole system is equipped with a dust collector, which adopts advanced electromagnetic pulse to automatically clean the dust. After the gas carrying dust enters the dust collector, the dust is filtered by the filter bag, and the dust attached to the outer surface of the filter bag is scattered under the action of the pulse blowback gas. The bottom is collected, and the filtered clean gas is discharged into the atmosphere through a fan.

Technical Parameters

| Model | Ball

mill model | Air classifier model | Total power | capacity | Fineness | Classification accuracy | Filter area | Dust concentration | Work system |

| GMF-100 | Φ1500*5700 | GF100 | ≤145 | 1.2-1.8 | 5-50 | D97 | ≥70 | ≤40 | continuous |

| GMF-200 | Φ1830*7000 | GF200 | ≤225 | 3.5-4 | 5-50 | D97 | ≥100 | ≤40 |

| GMF-400 | Φ2200*7000 | GF400 | ≤345 | 5-6 | 5-50 | D97 | ≥120 | ≤40 |

| GMF-500 | Φ2200*7500 | GF500 | ≤500 | 5-7 | 5-50 | D97 | ≥200 | ≤40 |

| GMF-600 | Φ2400*7500 | GF600 | ≤550 | 7-9 | 5-50 | D97 | ≥300 | ≤40 |

| GMF-800 | Φ2600*8000 | GF800 | ≤665 | 8-12 | 5-50 | D97 | ≥350 | ≤40 |

| GMF-1000 | Φ2800*8000 | GF1000 | ≤780 | 10-15 | 5-50 | D97 | ≥400 | ≤40 |

| GMF-1200 | Φ3200*9000 | GF1200 | ≤1200 | 15-20 | 5-50 | D97 | ≥500 | ≤40 |