Introduction

Quartz sand dryer is a rotary dryer, considering the characteristics of Silica sand, the internal structure and raw materials of the mine dryer are improved to meet the special needs of Silica sand production. The equipment is also applied to mine, metallurgy, cement, chemical and other industries.

Mine dryer is widely used in building materials, metallurgy, chemical industry, cement industry, drying slag limestone, pulverized coal, slag, clay and other materials. The mine dryer is mainly composed of a rotary body, a lifting plate, a transmission device, a support device, and a seal ring. It has the advantages of reasonable structure, excellent production, high output, low energy consumption and convenient operation.

Advantages

1. Dryer cylinder is welded with 304 stainless steel, high purity and no pollution.

2. There is a lifting device inside to make the material evenly dispersed, which is conducive to water evaporation and external insulation.

3.Biomass feedstock or natural gas can be used as heat source,with high thermal efficiency, environmental protection without pollution.

4. The entire equipment structure is simple and reasonable, easy to operate, low failure rate, easy maintenance.

5. The whole production line is equipped with a high temperature and environmental protection dust collector. No dust and pollutants are emitted during the entire production process.

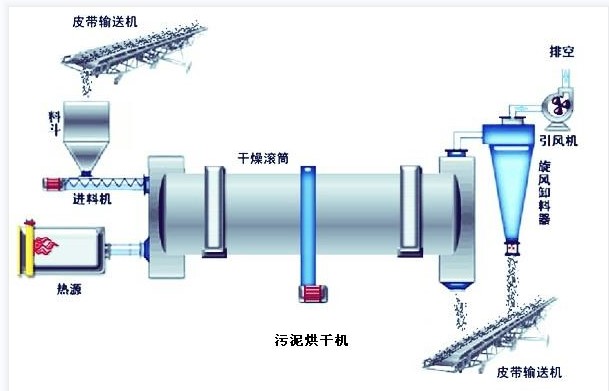

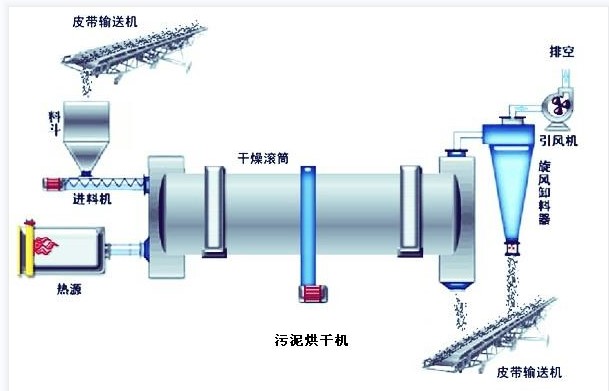

Working Principle

The wet material is sent to the hopper by a belt conveyor or a bucket elevator. The feeder of the hopper then enters the feed end through the feed pipe. The slope of the feed pipe is greater than the natural inclination of the material so that the material can flow smoothly into the dryer. The dryer drum is a rotating drum slightly inclined to the horizontal line. The material is added from the higher end, the heating body enters from the low end, and it is in countercurrent contact with the material. There is also a heating plate and the material along with the material flow into the cylinder. The plate is installed on the inner wall of the cylinder. Its role is to copy the material. It is also sprinkled up so that the contact surface of the material with the air flow is increased to increase the drying rate and promote the material advancement. After drying, the material is discharged into the finished product warehouse by falling onto the conveyor belt through the discharge port.

Technical Parameters

| Model | GHG-1 | GHG-2 | GHG-3 | GHG-4 | GHG-5 | GHG-6 |

| Roller dia(m) | 1.2 | 1.5 | 1.8 | 2.2 | 2.4 | 3.0 |

| Roller length(m) | 10 | 12 | 14 | 16 | 18 | 20 |

| Roller speed(rpm) | 6-8 | 4-6 | 3-4 | 3-4 | 2-3 | 2-3 |

| Initial moisture of material(%) | 6-20 | 6-20 | 6-20 | 6-20 | 6-20 | 6-20 |

| Material final moisture(%) | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| Higher intake air temperature(℃) | 750-900℃ | 750-900℃ | 750-900℃ | 750-900℃ | 750-900℃ | 750-900℃ |

| Capacity | Block material | 6-10 | 10-20 | 15-25 | 20-30 | 25-35 | 35-45 |

| Sand | 2-4 | 5-9 | 8-12 | 12-16 | 14-20 | 18-23 |

| Power(kw) | 12 | 16 | 22 | 37 | 45 | 75 |